Applications

Few examples:

- Press work

- Drilling

- Threading - Tapping

- Notching – Chipping - Stitching

- Punching

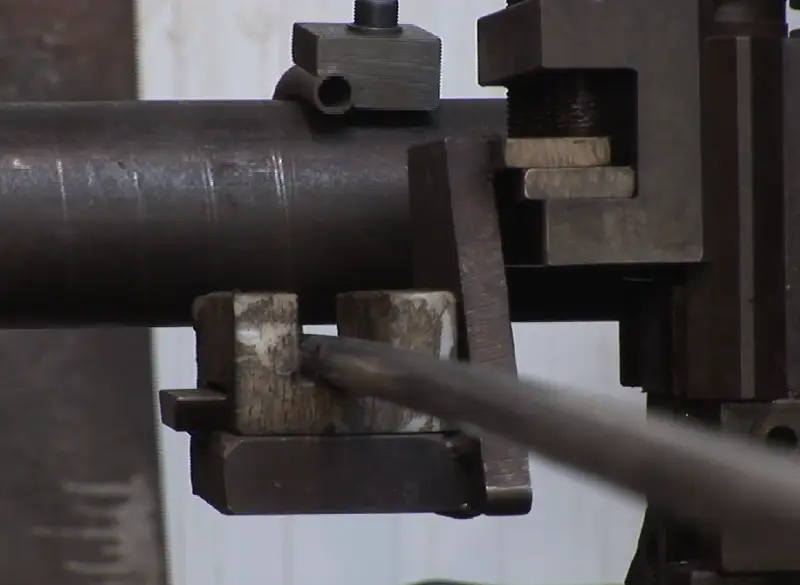

- Reducing - Flaring

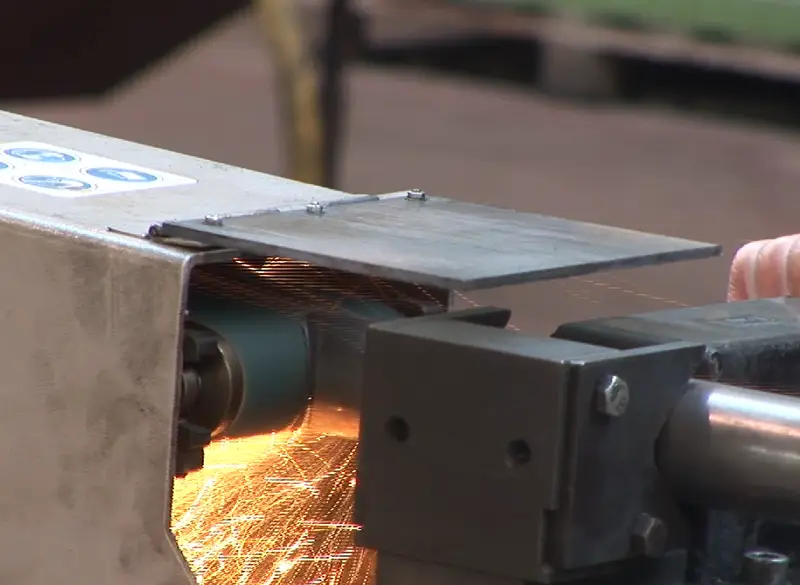

- Cutting

- Shaping

- Chamfer

- Angle cutting

- Sizing & calibration on template

- Turning - Milling

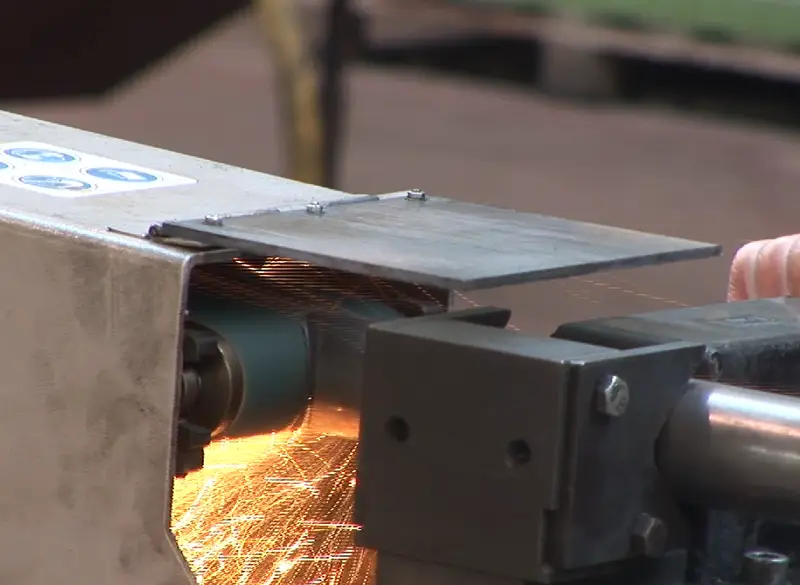

- Plasma cutting

- Tube-end forming

Other services :

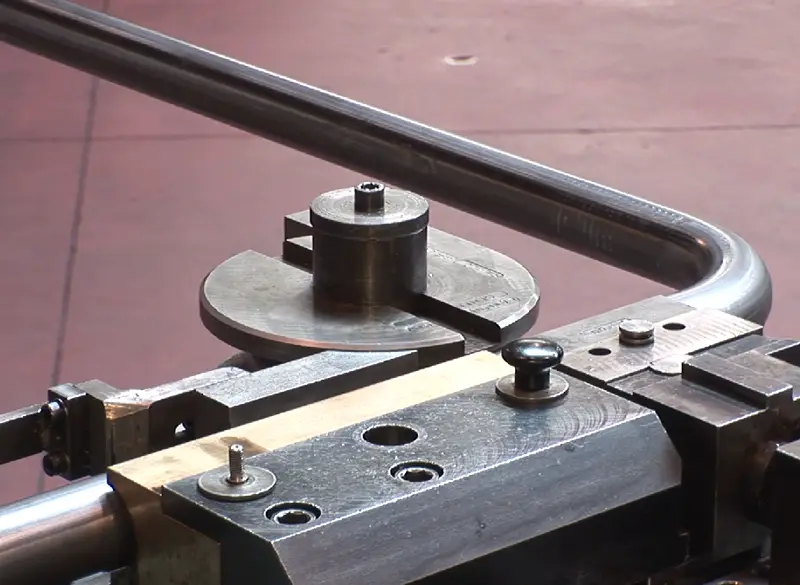

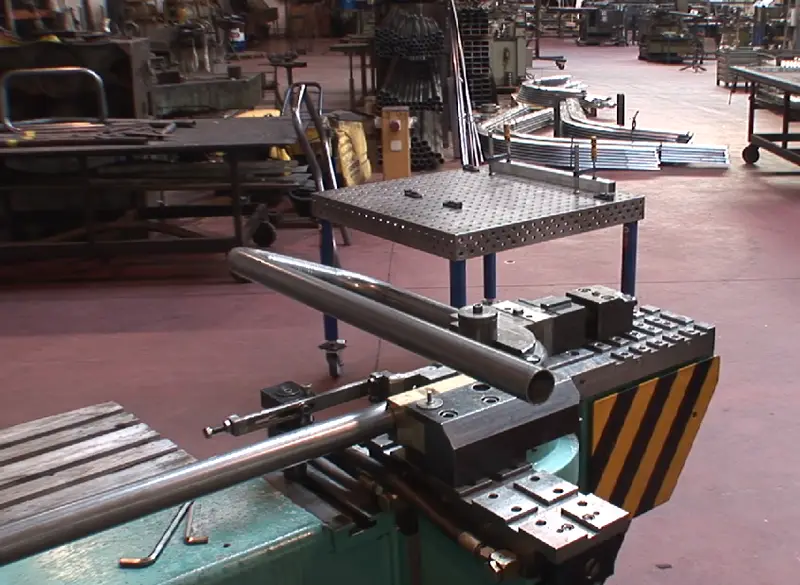

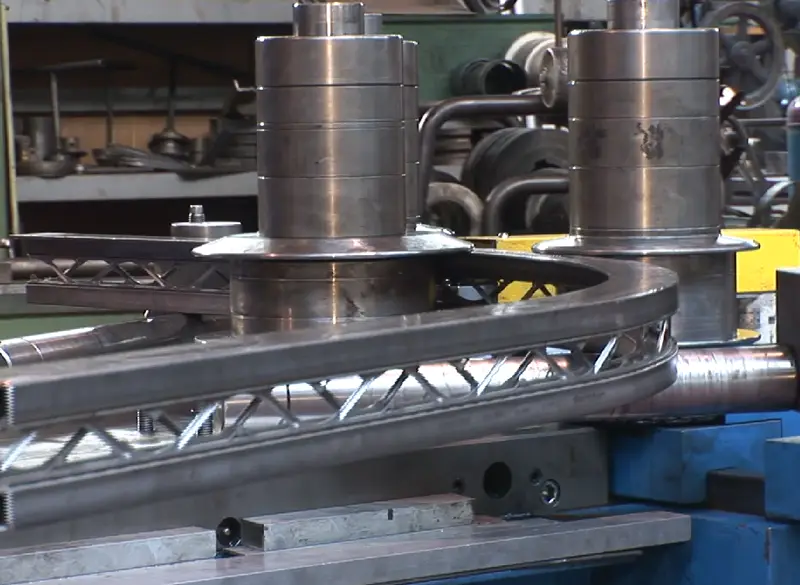

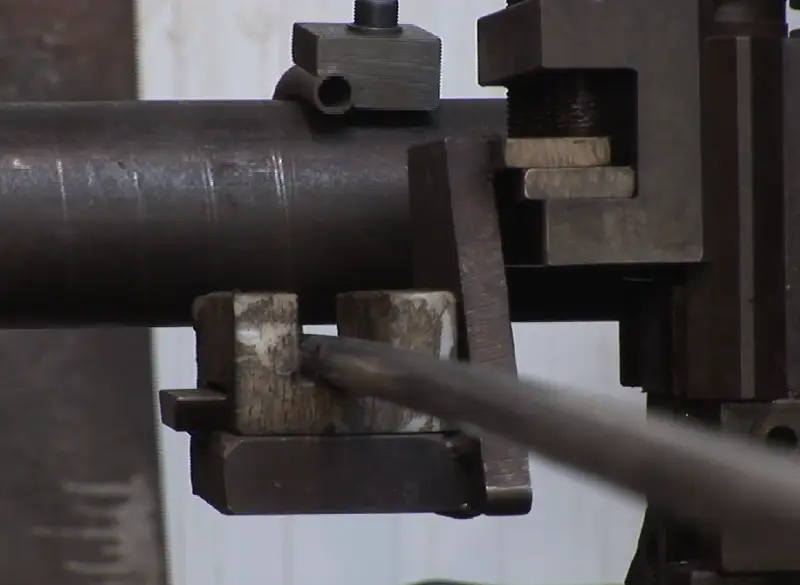

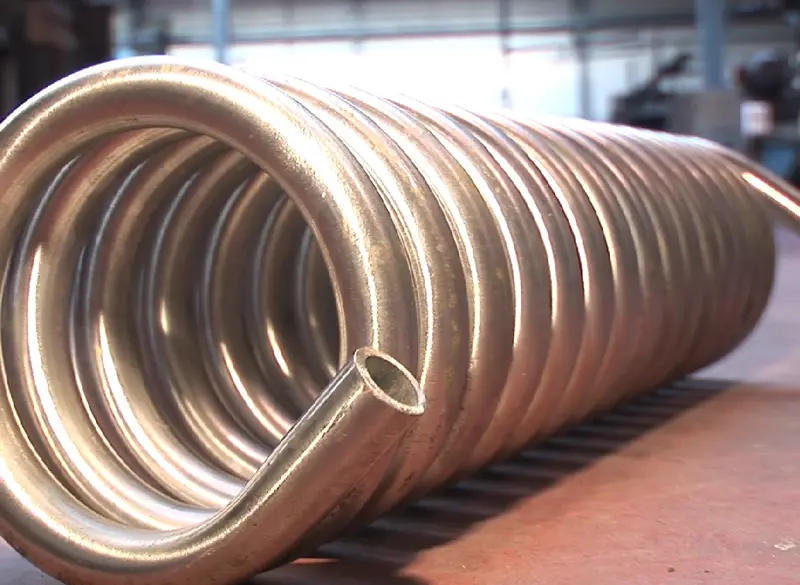

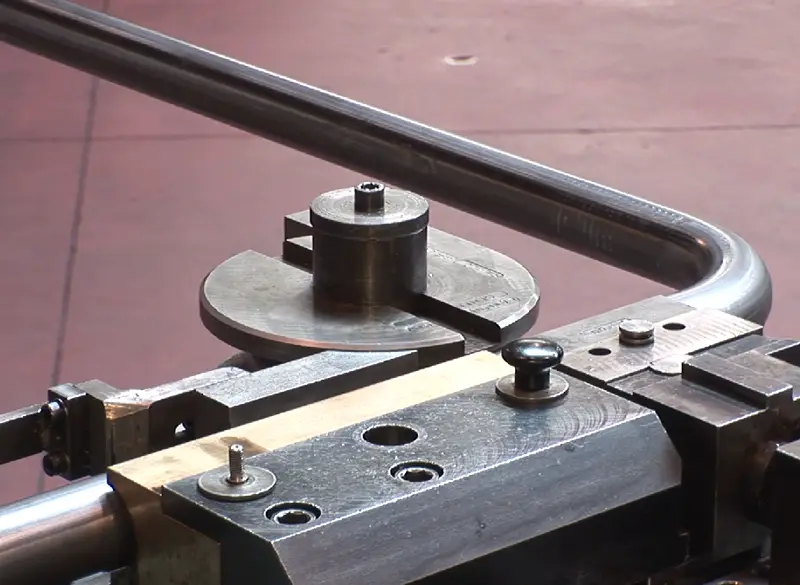

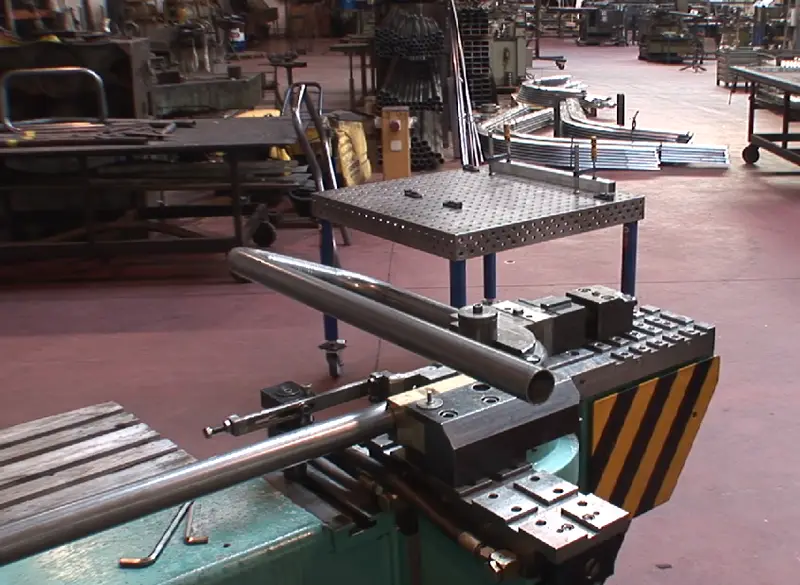

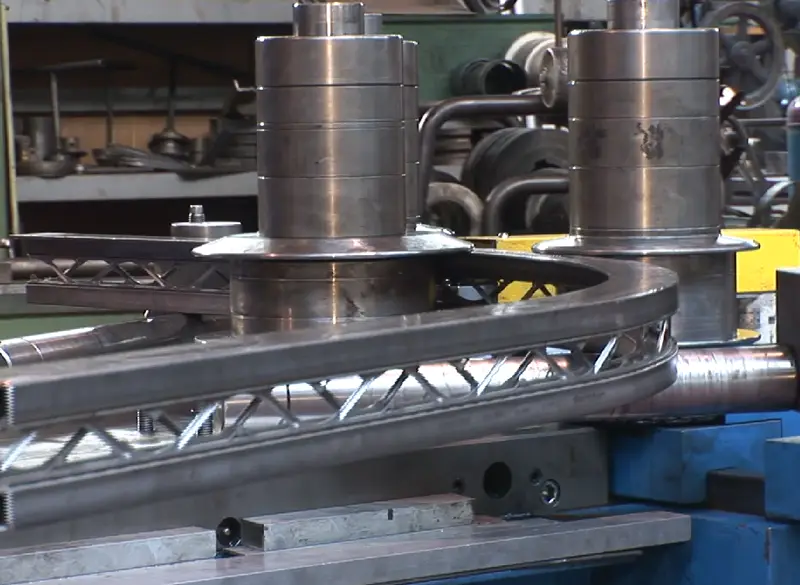

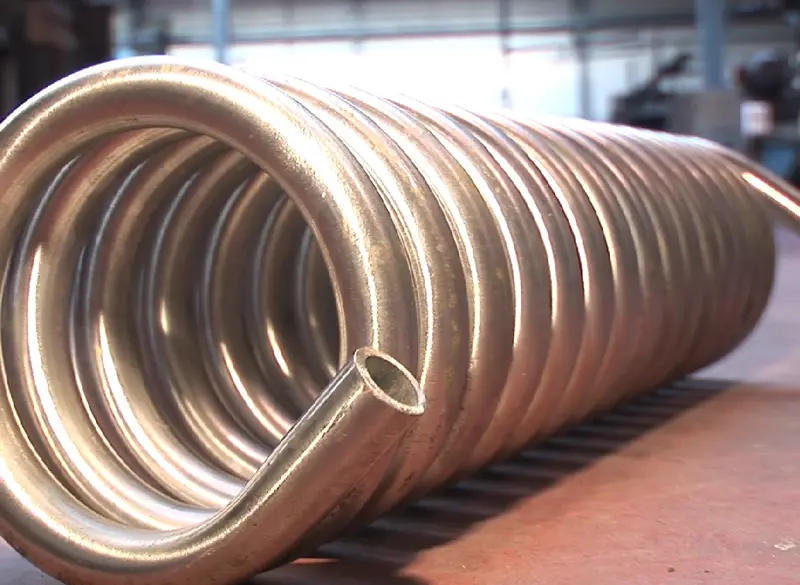

- Tube and section bending

- Welding

Do not hesitate to call on CIMESAC for all your machining work! We have the equipment and skills necessary to produce high-quality parts with precision. Thanks to our experience, reputation and technical capabilities, we are able to meet your specific needs in terms of deadlines and quality. We can also offer our services for pipe bending, metal profile bending or semi-automatic welding. Contact us without delay to discuss your projects or to obtain a detailed quote.

FAQ

Machining is a set of metal fabrication techniques that aim to shape parts to precise specifications. Among the many techniques used in various machining is press forming, which involves deforming metal parts by pressing them between two dies. This method is commonly used in the production of mass-produced parts, such as automotive components and hardware parts.

Another important machining technique is drilling, which involves creating holes of different sizes in metal materials using a drill or drilling machine. Threading and tapping are related processes that create threads inside holes to allow the screwing of bolts and other fasteners.

Notching and pricking are techniques used to create patterns and textures on metal surfaces, while punching is used to punch holes of specific shapes in metal materials. Necking and flaring are processes that change the shape of metal tube ends to suit different applications.

Parting off is used to divide metal materials into smaller sections, while beveling is used to create decorative patterns and details on metal surfaces. Chamfering is a type of bevel cutting that is used to create beveled edges on the edges of metal parts.

Angle cutting and sizing are used to cut metal materials at specific angles and to precise lengths, while jigging is used to verify the dimensions of manufactured parts and ensure they meet required specifications.

Turning and milling use machine tools to remove material from metal parts and shape them into the desired shape. These techniques are used in many manufacturing processes, including the manufacture of machine parts and industrial equipment.

Plasma cutting allows thick metal materials to be cut using a hot plasma jet. This technique is commonly used in the manufacturing of large metal parts and in shipbuilding.

Finally, various shapings at the ends of metal tubes help to suit different applications, such as welding, assembly and fastening.

Machining is therefore a set of essential metal manufacturing techniques that can create a wide variety of metal parts with precision and efficiency.

Common materials that are machined include metals such as steel, aluminum, copper, as well as plastics and some composites.

Machining produces parts with precise dimensions and a high-quality surface finish, suitable for a wide variety of industrial applications.