Bending

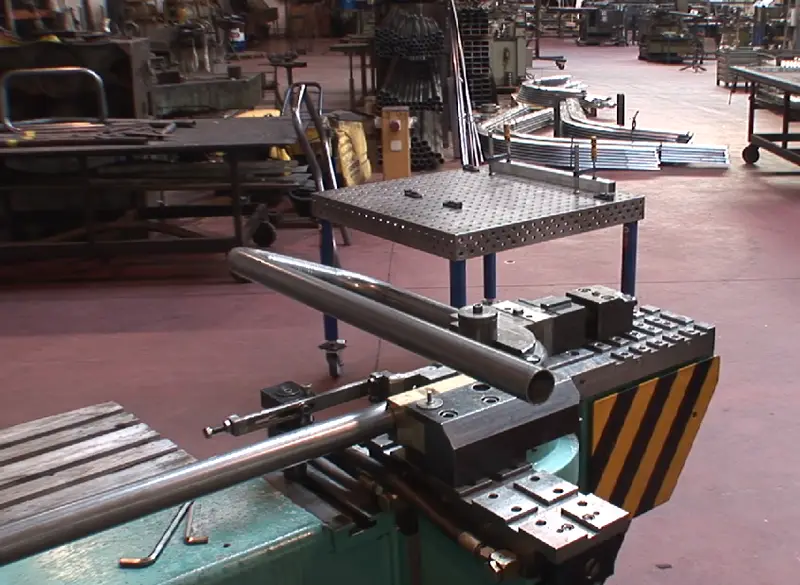

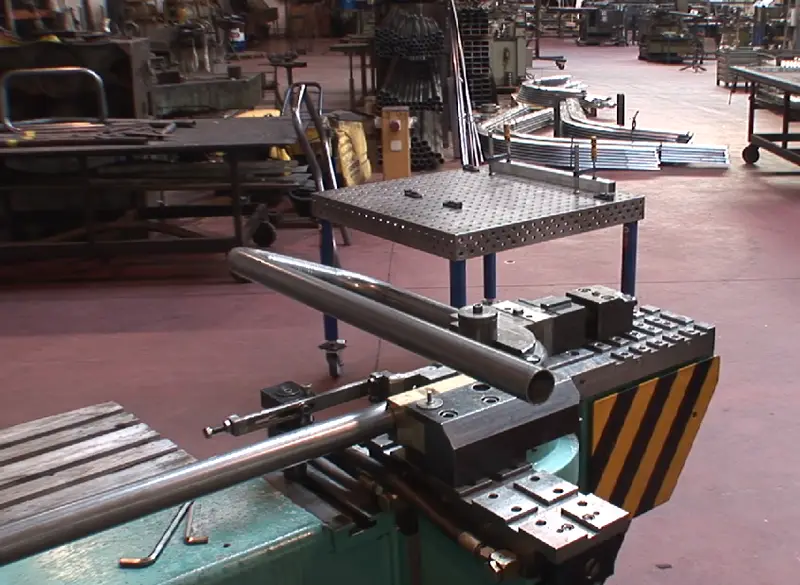

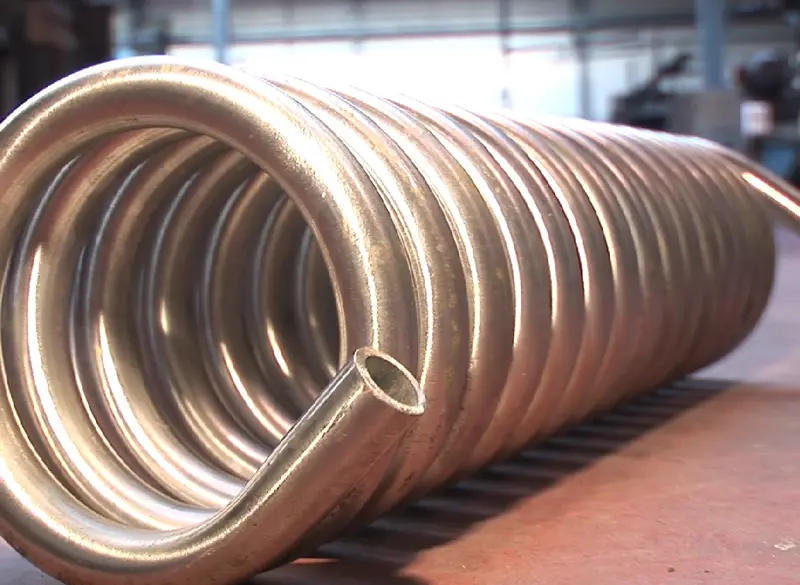

At CIMESAC, our ability to meet the varied needs of our customers is based on our wide selection of machines and our range of specialized tools. Whether it is the production of prototypes or the manufacture of series parts, we offer constant flexibility and quality. Our bending of metal profiles is carried out cold, thus ensuring the maintenance of the mechanical properties of the material, whatever the required radius of curvature. Whether for small or large scale requests, we are equipped to respond with precision and efficiency, thus offering our customers a solution adapted to their specific needs.

Applications - Few examples of section bending :

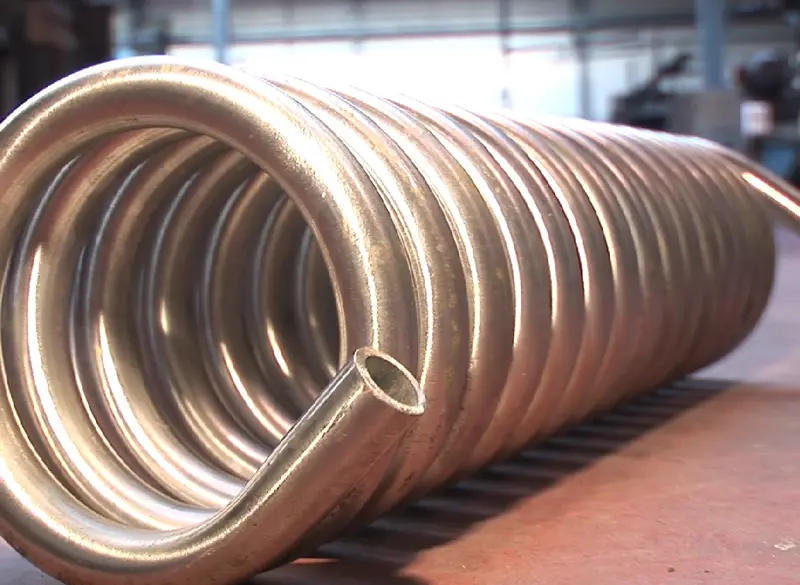

- Bending of sections and profiles from most metal and alloys, as steel, aluminium, copper, stainless steel, brass, etc ...

- Bending for the metal joinery with special profiles manufactured by Forster, RC System, Van Beveren, Janssen, Sapa, and many other companies including profiles with a thermal break

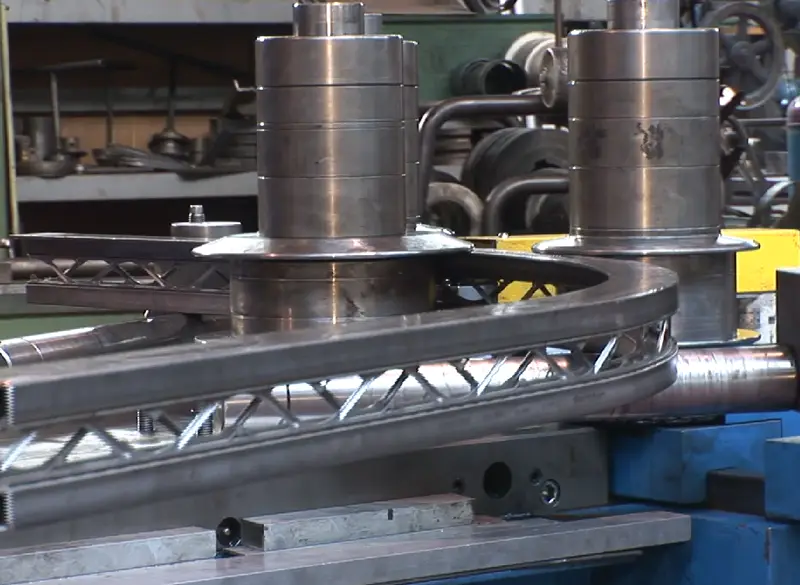

- Bending of extruded aluminium profiles. Even with complex profiles like multicavity, custom profiles, exotic shape profiles, etc

- Bending of all common profiles (i.e. T, U, V, L, etc …) in steel, stainless steel and other metals

- Bending of heavy sections for metal construction, like UPN, UAP, IPE, HEA, HEB, HEM profiles

- Flange manufacturing

- Accessories for the metallery

Activity sectors – Few examples :

- Metal joinery

- Construction metallery

- Metal construction

- Metal furniture manufacturing

- Equipment for industrial facilities (chemical, petrochemical, pharmaceutical, food, etc.)

- Manufacture of agricultural machinery

- Equipment for railway, naval, military, nuclear and energy sectors

- Equipment parts for agricultural machinery,

- rail, naval, military, nuclear and energy sectors

- Manufacture of parts for gates and fences

- Manufacture of protective equipment parts such as rails, fences, handrails, bumpers, etc …

- Manufacturing of urban furniture parts

At CIMESAC, we are committed to meeting the specific needs of our customers by offering custom-made metal profile bending, adapted to their particular requirements. Whether for complex projects or unique designs, our experienced team is ready to take on any challenge. Do not hesitate to consult our achievements to discover the extent of our know-how. Contact us to realize your ideas or to obtain a personalized quote.

FAQ

The design of the profiles is a technique for metal fabrication based on the shape of the metal profiles, the shape of the tubes, the poutrelles, the cornices of the bars, and the specific shapes. The process is based on the specification of machine tools used in the machine, using the different methods such as rolling, roller bending or pressure bending to bend the profile.

The machines are designed for manual operation, semi-automatic or automatic automation, and the use of different equipment and functions for the dimensions and specification of the profiles of the machine.

The profiles are widely used in various industrial sectors, in construction, architecture, metal structure fabrication, metal joinery, automobile industry and aerospace. In addition to the creation of a large variety of products and pieces, all the elements used for the construction of machines, along with the industrial equipment and decoration products.

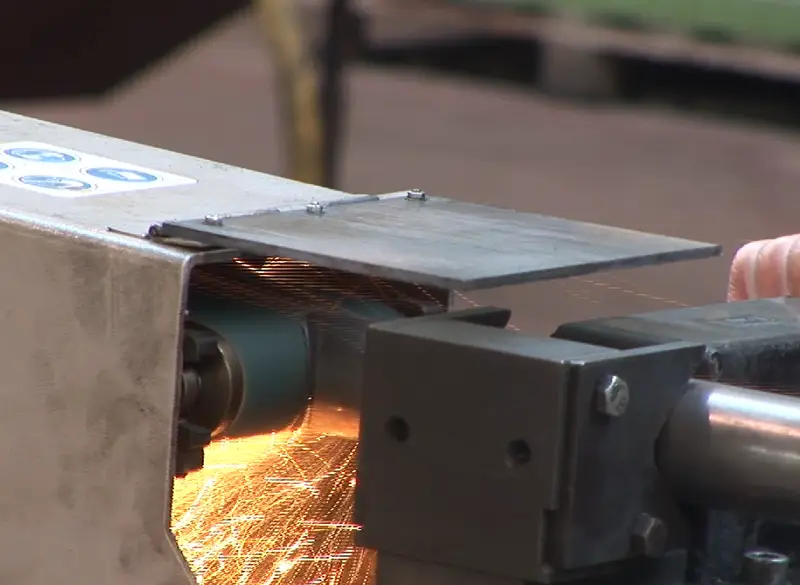

And in addition, production techniques such as laser cutting process, rolling, bending and welding are used for the transformation of the profiles and the processing and assembly of the pieces. The choice of profiles and the great flexibility of conception and the realization of the design and preparation methods guarantee the quality and durability of the final products.

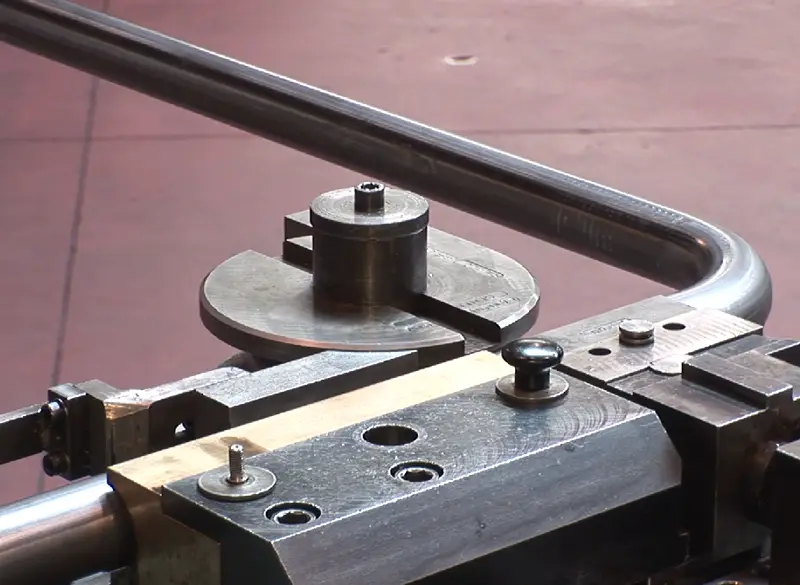

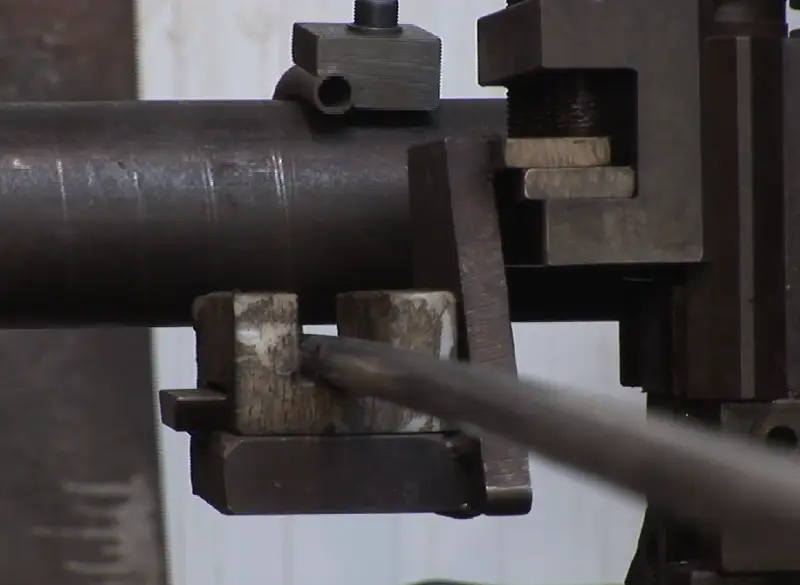

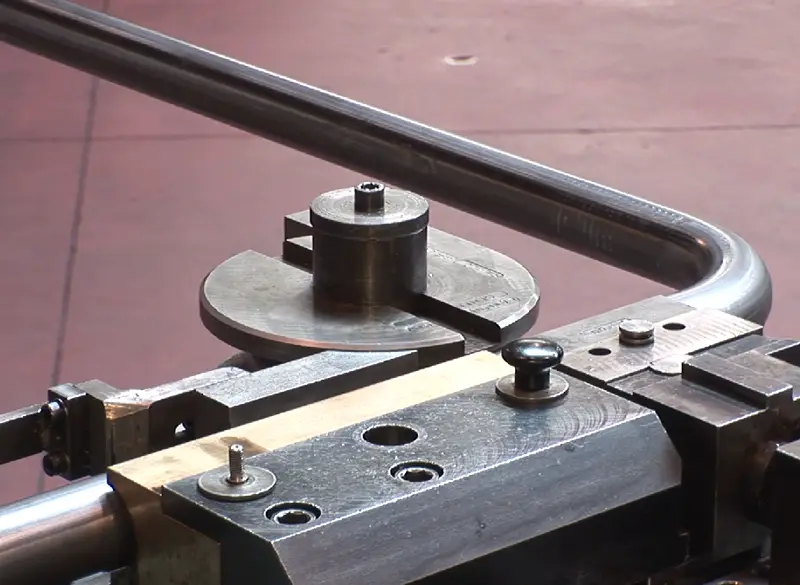

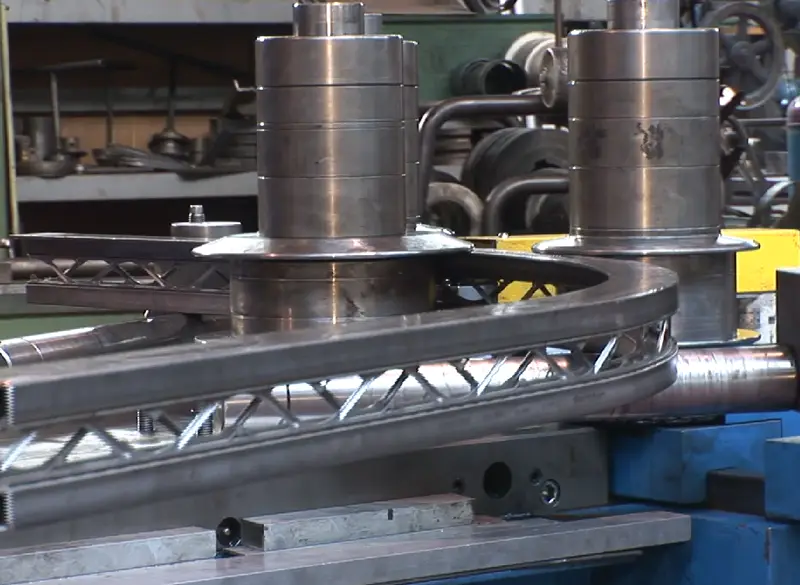

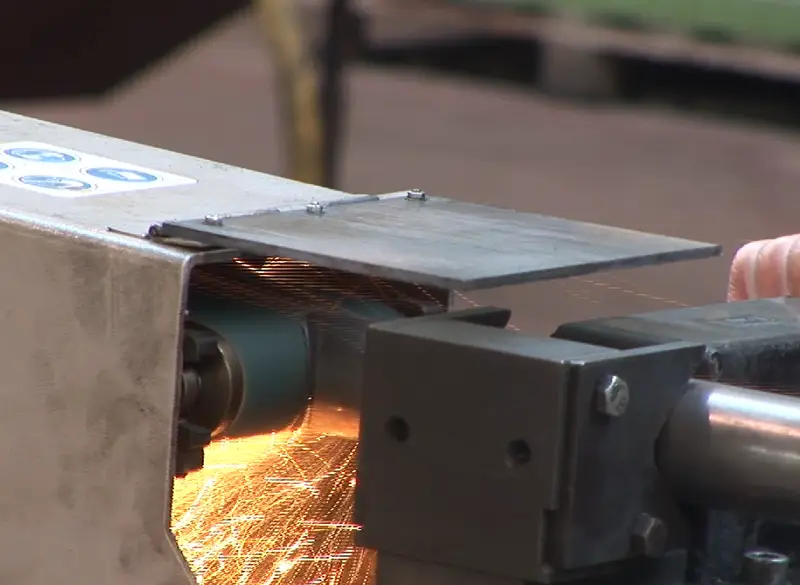

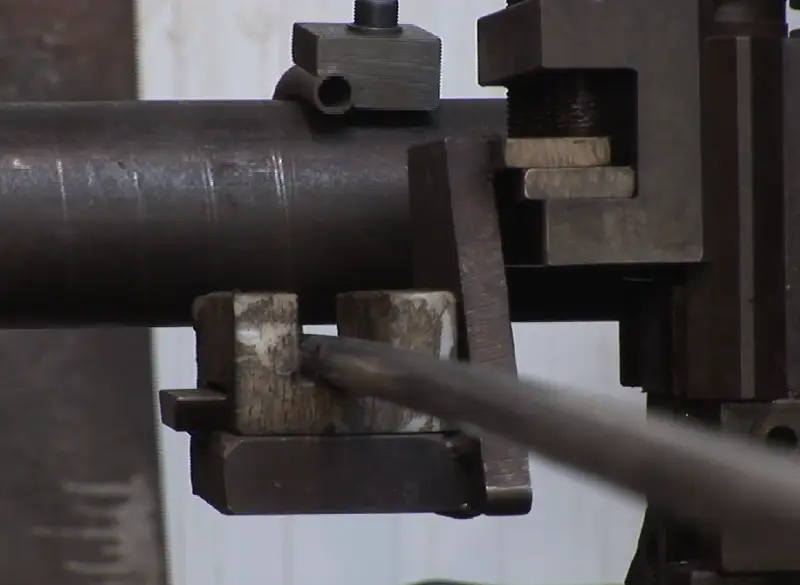

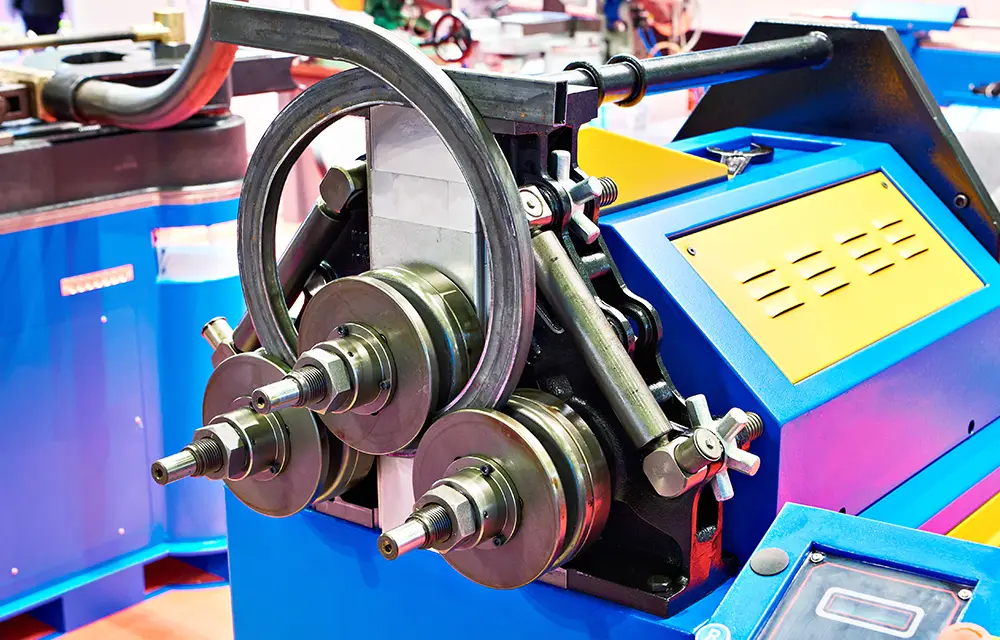

Our machine park, equipped with CNC and hydraulic bending machines, allows us to bend a wide variety of steel profiles. This includes tubes, beams, angles, and bars, as well as hollow sections of different diameters. The specific rollers and rolling techniques of each machine ensure precise deformation without damaging the metal. Thanks to this advanced technology, we can work profiles for any type of industry, offering tailor-made solutions that meet the technical and aesthetic requirements of our customers."

Bending profiles with our electric and hydraulic bending machines offers several advantages. This technique allows great design flexibility, ideal for complex architectural projects or specific metal constructions. In addition to laser cutting and folding machine forming, bending ensures that each part is precisely adapted to the needs of the project. The ability to create curved and complex shapes also increases the scope of possible applications, improving the efficiency of the service and the quality of the final work. By combining semi-automatic welding and traditional techniques, we guarantee the durability and functionality of the structures.

Absolutely, our custom tube and profile bending service is at the heart of our offering. With our digital bending machines and sheet metal cutting and forming tools, we are able to meet specific requests, regardless of the complexity of the profile or the industry sector concerned. Our machines allows for precise adjustment of the rollers and tools for each type of profile, ensuring that each bend meets the exact specifications of the customer.