A cutting-edge technique

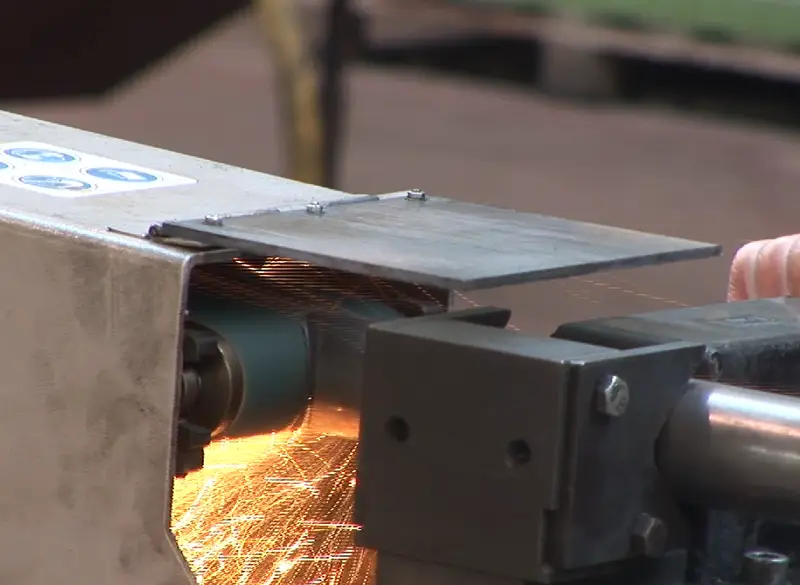

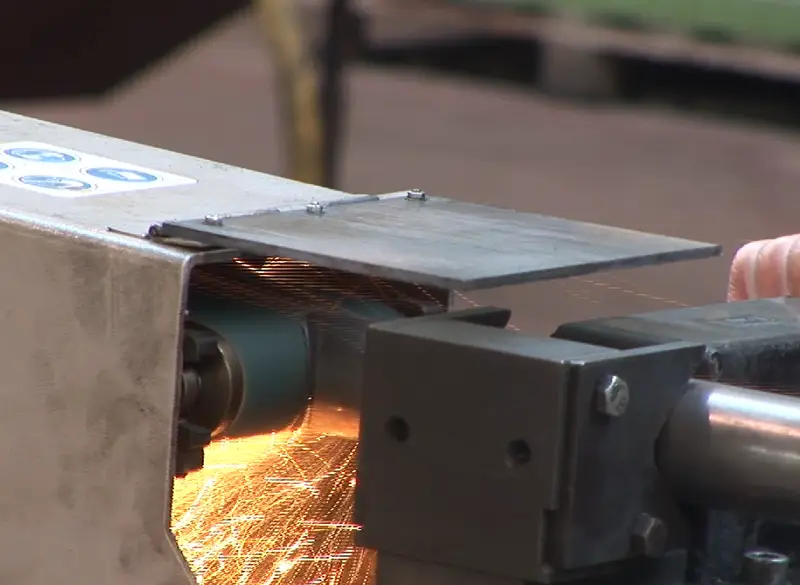

Semi-automatic welding, also known as MIG (Metal Inert Gas) or MAG (Metal Active Gas), is a widely used method for welding different types of metals, including steel. At CIMESAC, we carry out:

- MIG – MAG welding

- TIG welding

- Brazing - Silver brazing

Welding alternatives

In addition to MIG/MAG welding, other welding processes are also widely used in Belgium. Shielded arc welding, also known as MMA or stick welding, is commonly used for on-site welding applications and repair work.

TIG welding, which uses a non-consumable tungsten electrode and an inert shielding gas, is often preferred for applications requiring high precision and high-quality welds on thin or sensitive materials.

CIMESAC: a quality service

Thanks to our technical expertise and our advanced equipment, we are able to produce high quality welds in the field of industrial piping.

CIMESAC offers tailor-made solutions adapted to the specific requirements of each project.

With a commitment to excellence and a constant focus on customer satisfaction, CIMESAC is a trusted partner for many companies in Belgium and elsewhere in Western Europe. Whether large series productions or tailor-made projects, CIMESAC is ready to take on any challenge in terms of semi-automatic welding of unmatched high quality and impeccable service.

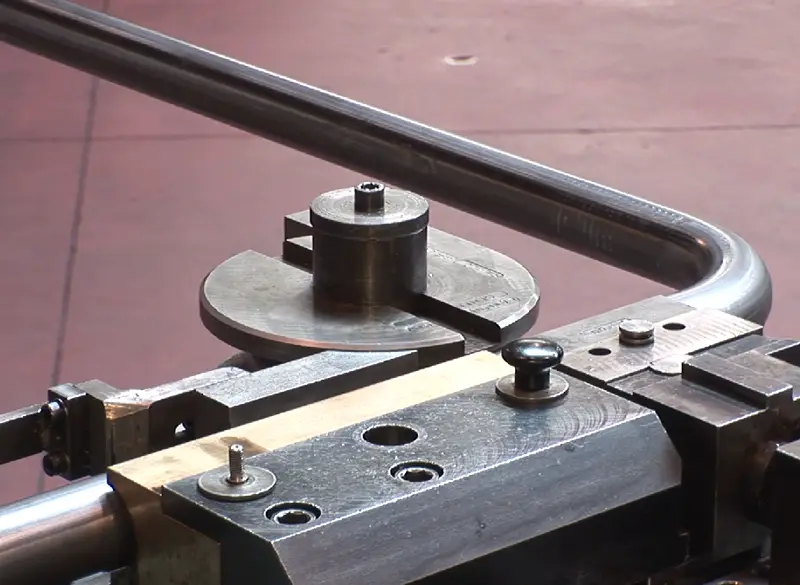

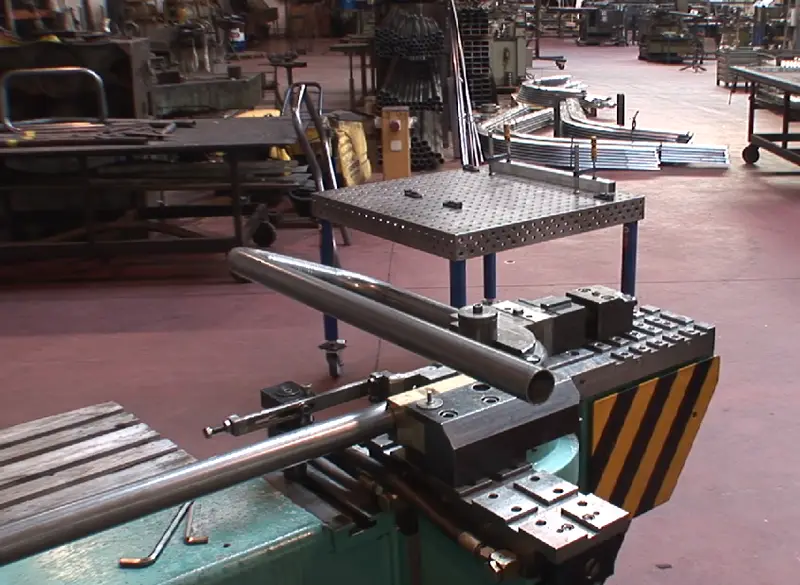

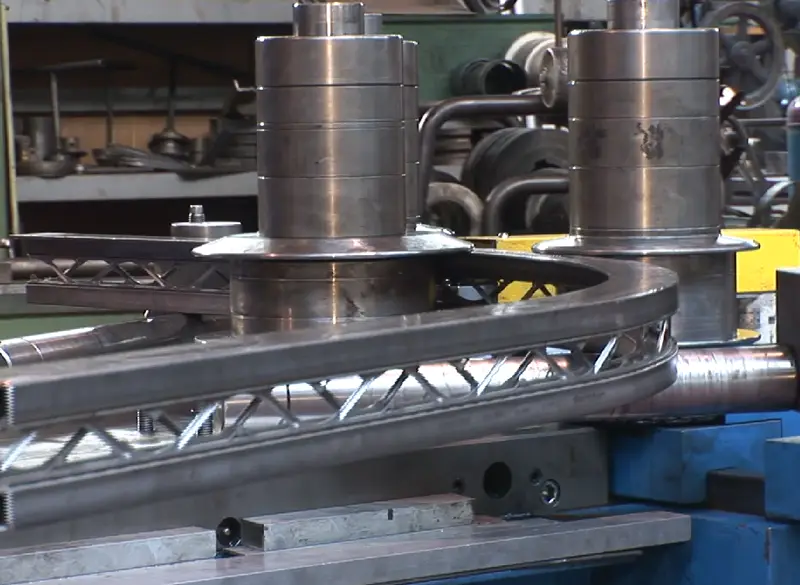

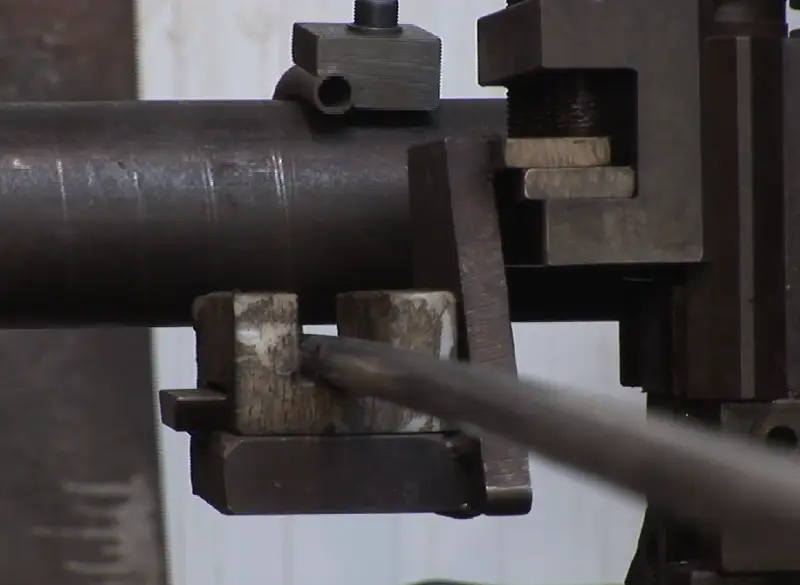

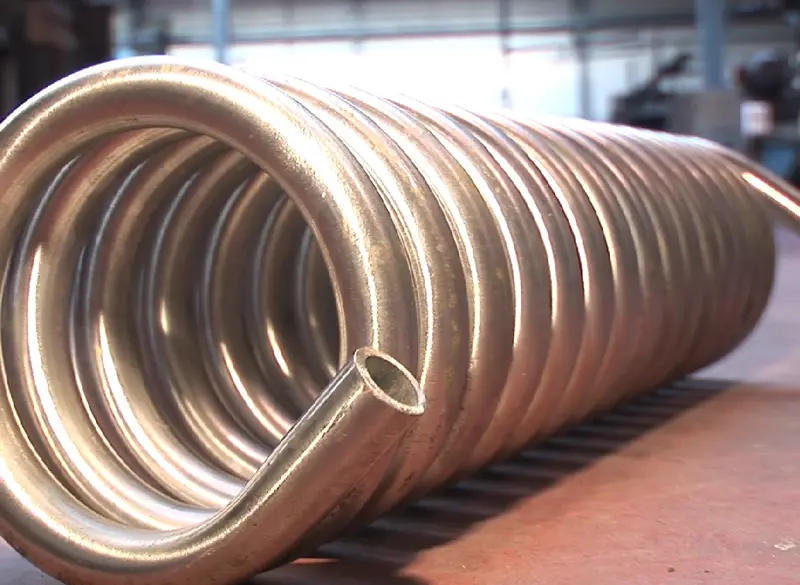

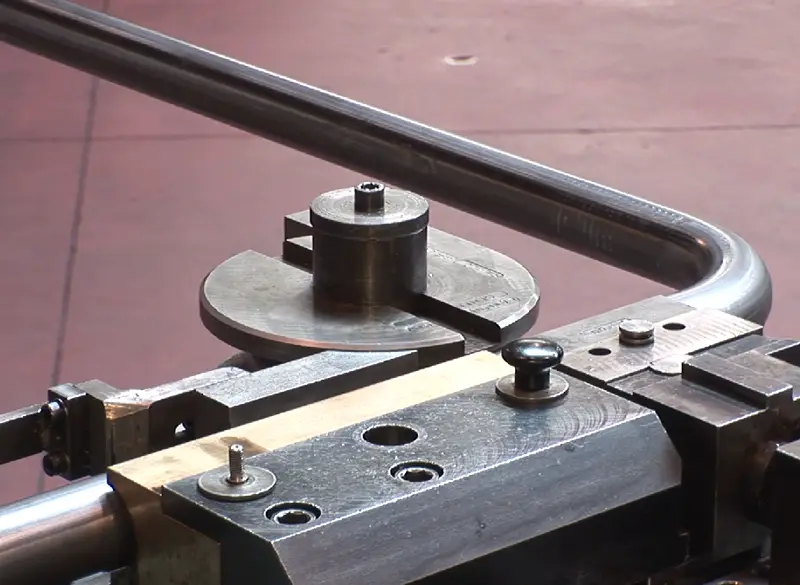

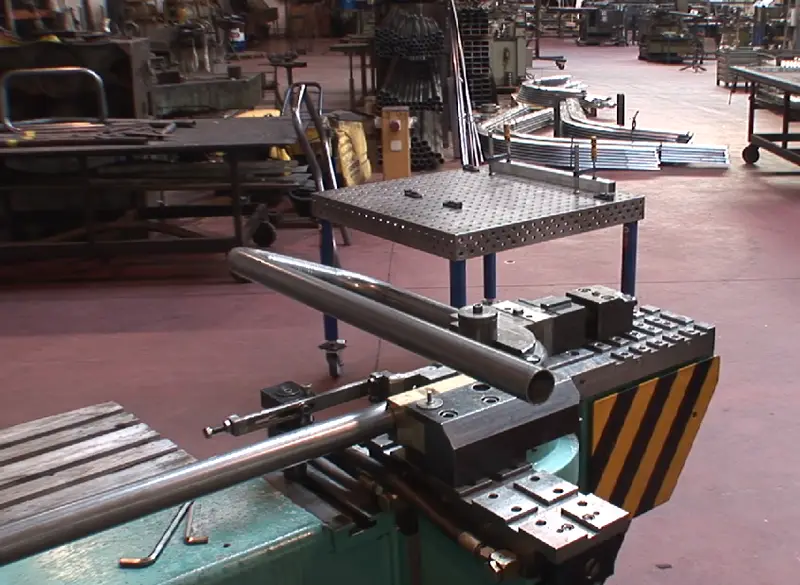

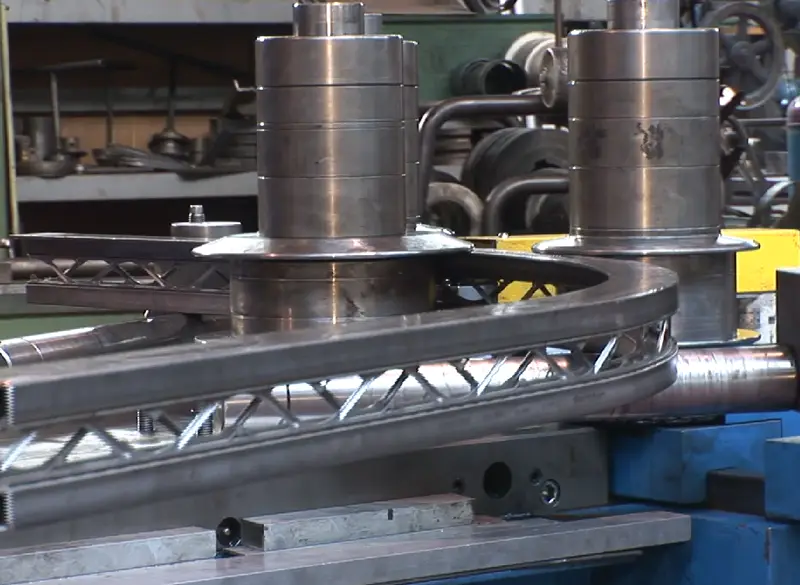

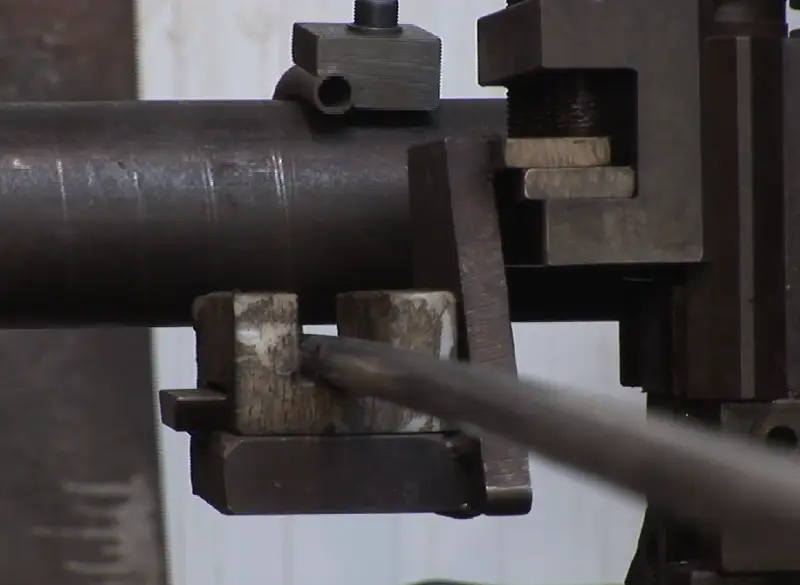

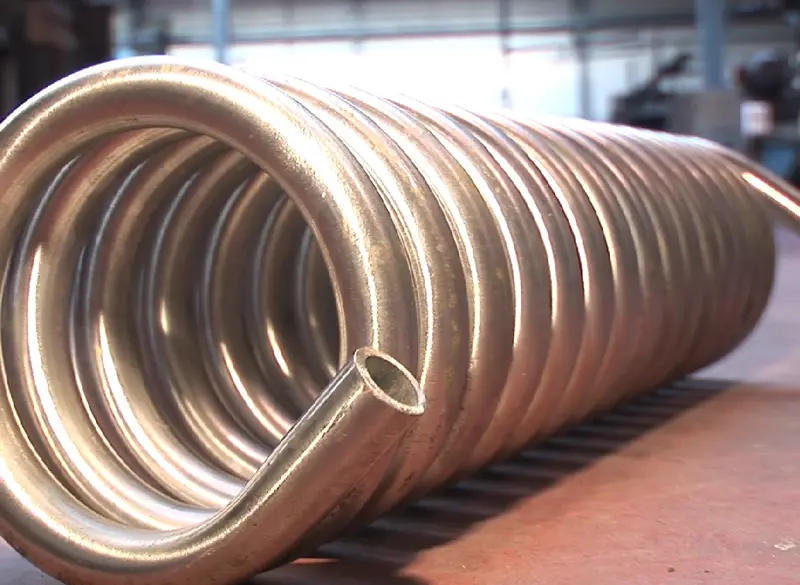

Bending and machining your parts

In addition to our expertise in pipe welding, our company offers tube and profile bending services, providing an aesthetic and cost-effective alternative that is often more attractive than welding. If you would like to learn more about our profile bending, tube bending and various machining services, please do not hesitate to contact us today. We are available to answer all your questions and discuss your specific welding, bending and machining needs.

FAQ

Welding creates strong, durable joints between metal parts, which is essential in many industrial fields, from construction to automotive engineering.

This semi-automatic welding technique involves the use of a specialized welding machine, equipped with a cored wire that feeds the filler metal into the welding zone. Shielding gas, usually CO2 or a mixture of inert and active gases, is also used to protect the weld pool from atmospheric contaminants and ensure clean, high-quality welds.

One of the key advantages of MIG/MAG welding is its ease of use and high productivity. CIMESAC workers can easily adjust the welding intensity and control the wire feed speed, resulting in uniform, high-quality welds with minimal effort. Additionally, our MIG/MAG welders are often equipped with advanced features such as arc monitoring and gas management, ensuring reliable and consistent performance.

The most commonly welded materials include steel, aluminum, stainless steel, copper, and brass, although welding can be used for a wide variety of metals and alloys.

TIG welding uses an electric arc between a non-consumable tungsten electrode and the workpieces to be welded, while MIG welding uses a continuous filler wire and shielding gas to create the electric arc.