Metal tube bending options

Upon request of our customers, we are able to create very specific bending tools for special tubes like oval, polygonal, square, rectangular, oblong, elliptical, triangular or finned tube.

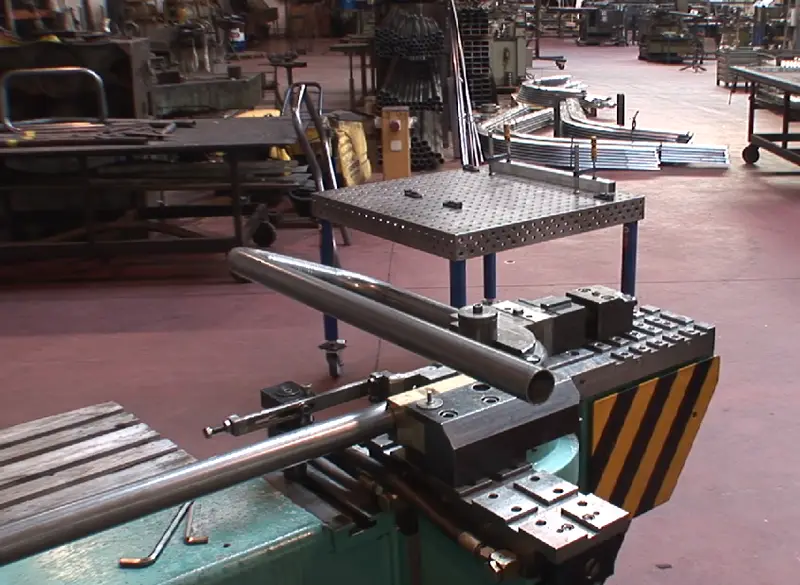

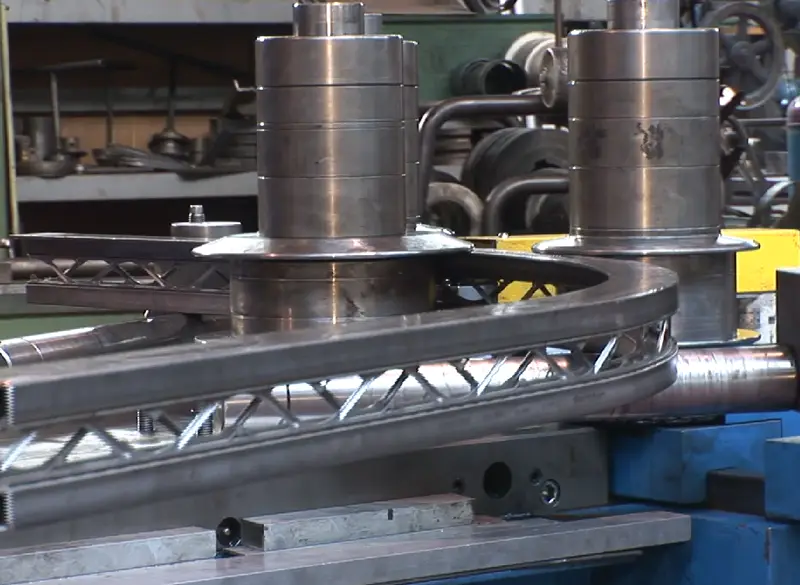

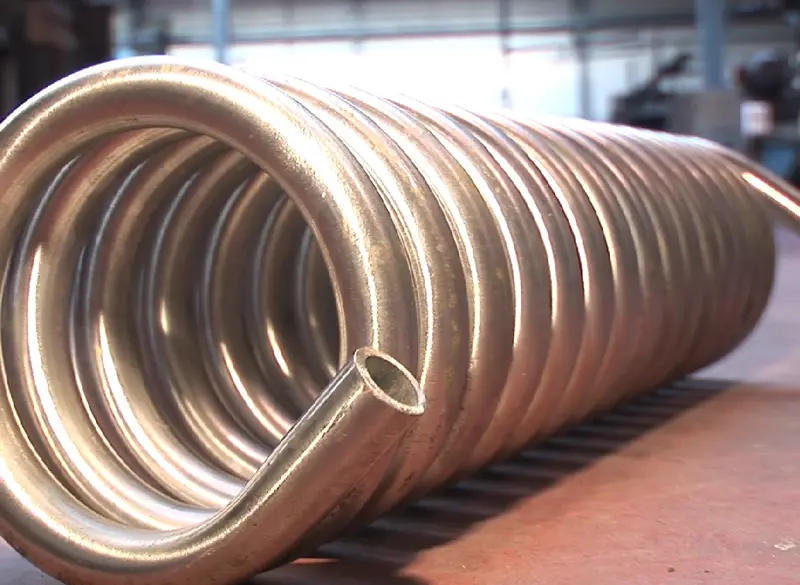

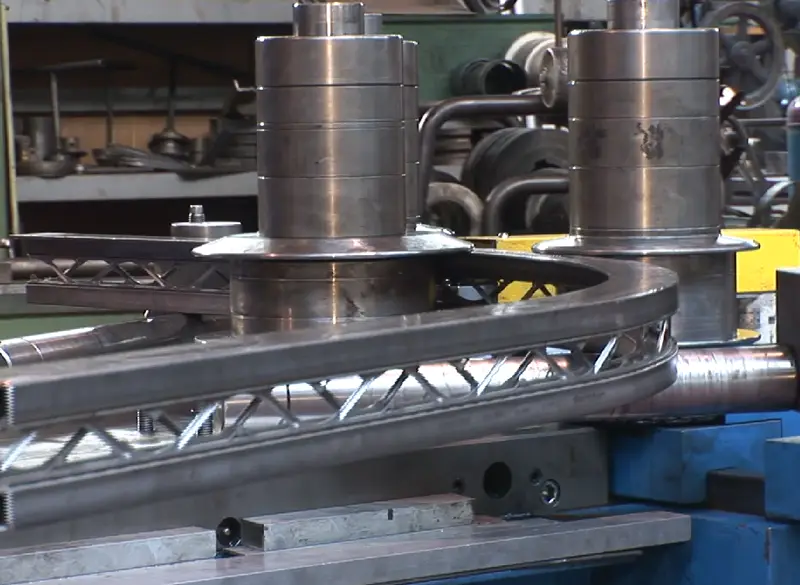

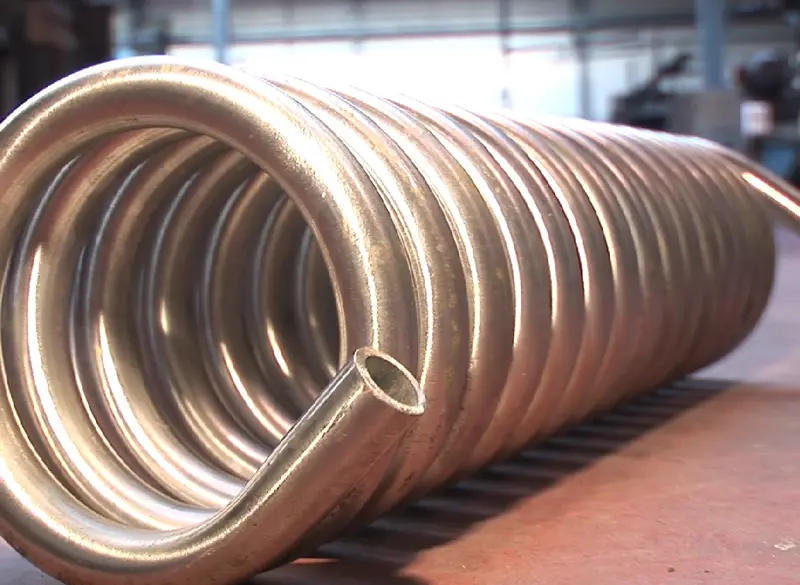

Our well adapted machine fleet and our expertise, allow us to create complex curved parts such as 3-dimensional structures, spirals, helical parts and other complex forms.

Our techniques and tools fit perfectly with all bendable metal or alloys (steel, stainless steel, aluminium, copper, brass, titanium, Hastelloy, Inconel, Incoloy, … Our flexible structure is adapted to the manufacturing of varying amounts, starting from a single prototype, but also to serial production.

Applications - Few examples of pipe bending :

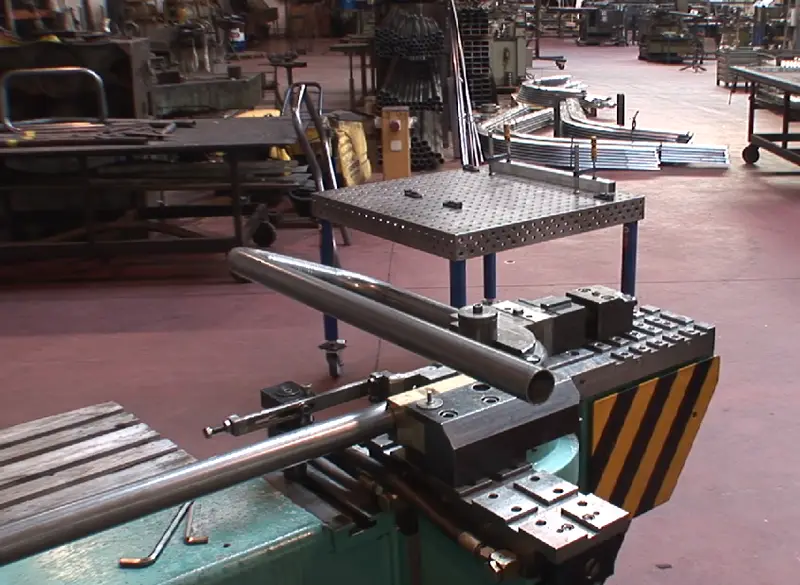

- Bending of round tubes from Ø 3 mm up to Ø 323 mm (12 inches)

- Press bending

- Small radius elbow (min. 1.25 x ND)

- Elbows for general industrial applications.

- Serpentine for heat exchanger. Flat, cylindrical, conic, bended tube bundles, …

- Elbow for pneumatique conveying

- Railings, handrails and tubular arched portal

- Tubular safety barriers

- Exhaust pipe elbow

- Tubular handrail and baserail for balanced staircase.

- Small thickness pipe elbow

Sectors of activities – Some examples

- Industrial facilities (chemical, petrochemical, pharmaceutical, food, etc.)

- Agricultural machinery and equipment

- Metallic construction

- Railways, naval, military, nuclear and energy sectors

- Metallic parts furniture manufacturer

- Building ironwork

- Automotive equipment and construction machinery

- Manufacture of safety and protective equipment

- Boiler manufacturer, heat production, cold production

- Pneumatic conveying systems

CIMESAC excels in the art of tube and pipe bending in Belgium and Northern France. Thanks to our recognized expertise, we offer customized bending solutions, whether for complex projects or standard needs, meeting the most rigorous standards in the industry. Do not hesitate to contact us for more information!

FAQ

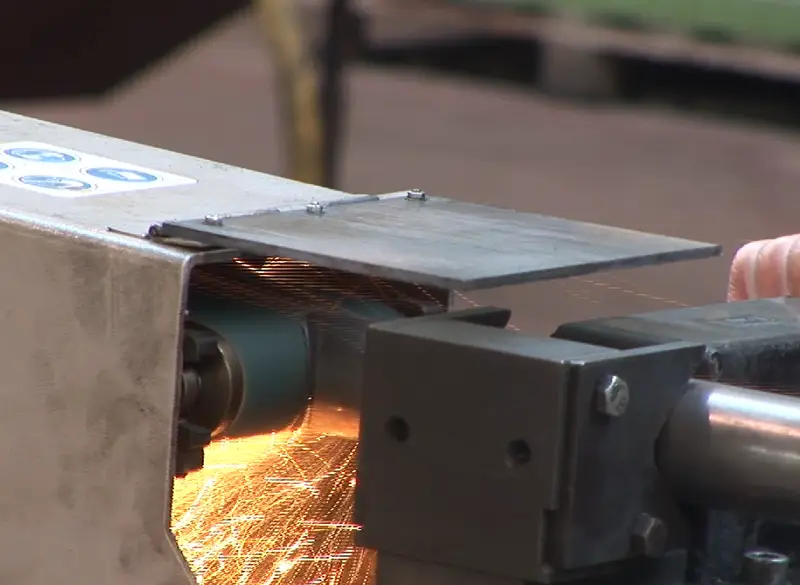

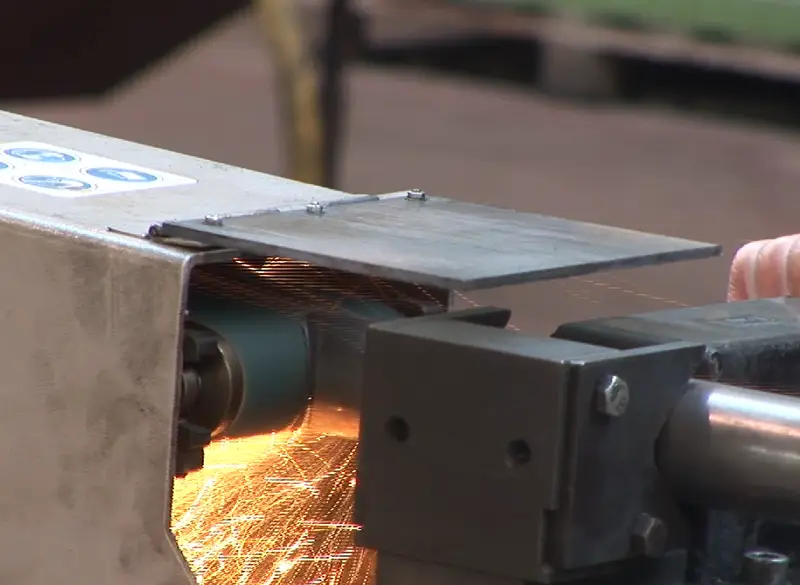

The "cold" bending of metal tubes is a deformation process at room temperature, generally carried out using specific machines called benders. This method allows to bend steel, stainless steel and other alloy tubes without heating them beforehand.

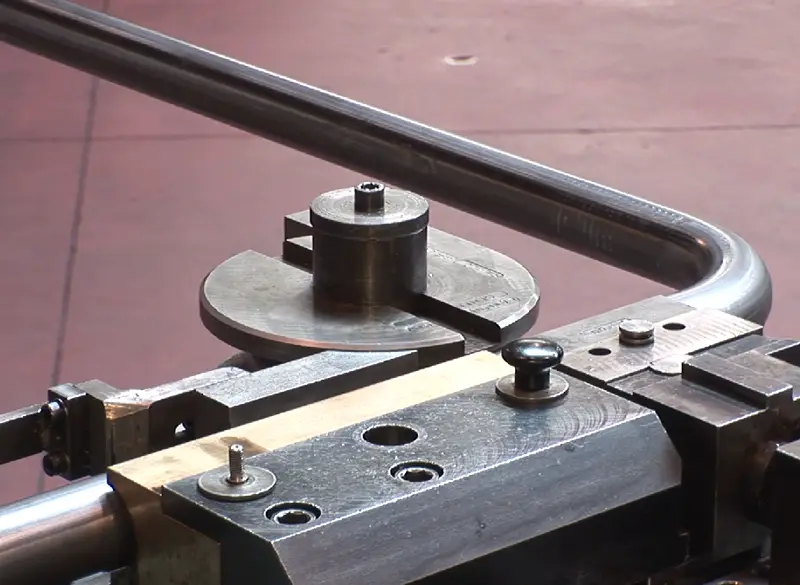

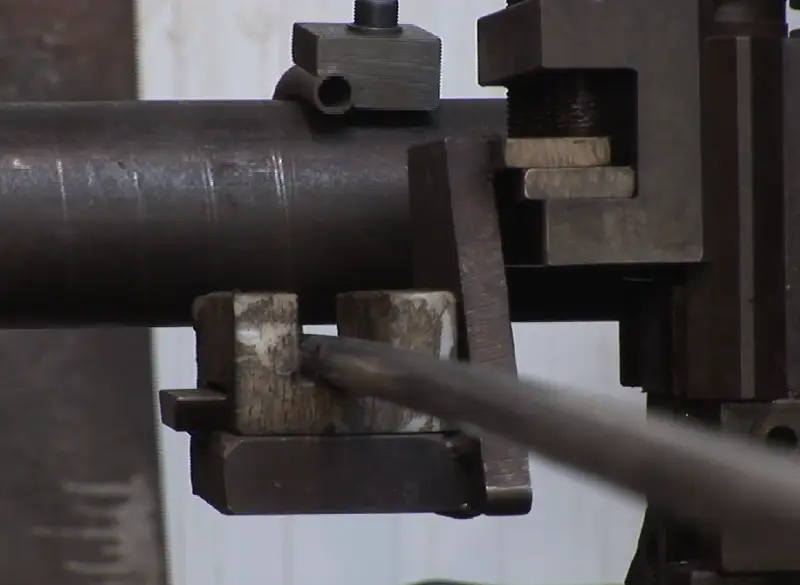

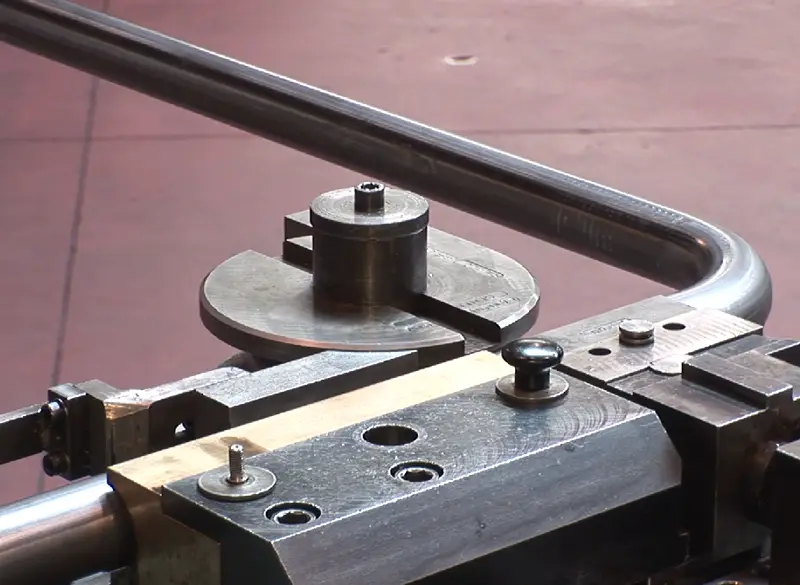

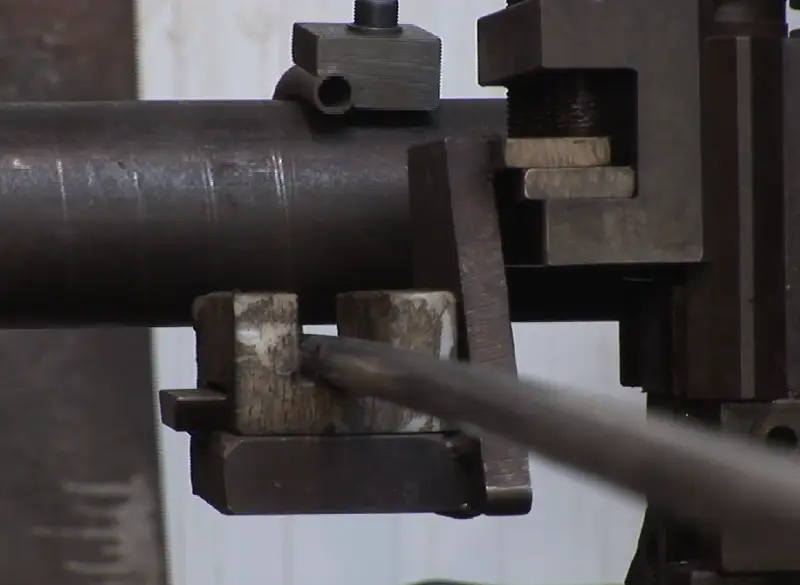

The benders can be manual or hydraulic, operating by pressure to bend the tube according to a predefined radius. The use of accessories such as bending pliers and bending dies allows to adjust the diameter and bending radius of the tubes. The bent tubes thus obtained are used in various industrial applications, in particular for the manufacture of tubular structures, fittings and gas accessories.

"Cold" benders offer bending flexibility, allowing to make standard bends or custom bends according to the specific needs of the project. Whether for standard diameter tubes or profile tubes, cold bending guarantees precise and high-quality results, with an average bending radius adjustable according to the design requirements. By using suitable tooling, it is possible to bend tubes of different materials and thicknesses, thus offering great versatility to meet the varied needs of the industry.

Whether for bending steel, stainless steel or other alloy tubes, cold bending remains an efficient and economical method for shaping tubes into curved or bent shapes, while preserving their mechanical properties.

Cold bending preserves the mechanical properties of the material, avoids thermal deformation and surface alterations, while offering greater precision and better reproducibility of bends.

Cold bending is suitable for a variety of materials, allowing pipes and tubes of different diameters to be efficiently handled. Manual or hydraulic benders, equipped with specific pliers and tools, can work aluminum, copper, as well as multi-layer materials. This method can also process spring steels and other strong metal alloys used in industrial applications requiring precision and strength.

The advantage of cold bending lies in its ability to bend materials without altering their properties, thanks to suitable tooling that includes bending and brake accessories. This equipment allows for precise bends, often required for gas or other pressurized fluid piping systems. The results obtained are not only aesthetic but also functional, offering angles and curves up to 360 degrees without compromising the integrity of the tube.

In summary, cold bending using a manual or hydraulic bender, supported by well-designed tooling, is ideal for shaping a wide range of metal materials, producing high-quality results that meet the strictest standards of various industries."

Thanks to its know-how and cutting-edge equipment, CIMESAC is able to meet the specific needs of each project for bending steel and other metal profiles, tubes, various machining or semi-automatic welding. We offer tailor-made solutions for a variety of industrial applications. In addition, by choosing CIMESAC, you are using a Belgian company, promoting local work, thus guaranteeing an efficient and personalized service.